Core Facilities and Service Group

Search term not found.

Core Facility

Imaging of Materials Systems

- The 3D visualization of complex functional and adaptive (micro)systems in biology and technology is one of the central challenges in basic research on adaptive and bio-inspired technologies and in the investigation of functional principles in biological systems as a source of ideas for new technical developments.

- Using existing and newly acquired equipment, it is possible to establish a specialized laboratory for microscopy and tomography of materials combined with an FIT competence network for 3D visualization.

- If you have any further questions regarding the costs (fee regulation), usage regulations and registration procedure, please contact the management of the Core Facility.

- Scientific Head: Prof. Dr. Anna Fischer

- Responsible Manager: Dr. Yi Thomann

Equipment

Talos 200X – HRTEM/HRSTEM

- 200 kV high-brightness X-FEG

- Modes: TEM, STEM, HAAFD, DF, DPC

- SuperX EDX System

- (limited) Cryo TEM, STEM

- TEM Holder: Double Tilt, High Tilt, Cryo

- Piezo-Stage 20 pm

- Low-dose technique

- Ceta 16 Megapixel Digital Camera

- Auto tilt series imaging

- Tomography reconstruction

- Application areas:

- Solid state inorganic and soft matter materials (metals, semiconductors, composites, polymers etc).

- 2D (up to atomic resolution) and 3D imaging.

- 2D EDX analytics (point analysis and mapping).

Talos 120C – TEM

- 120 kV LaB6 gun

- Double Tilt, High Tilt and Cryo Holders

- Ceta 16 Megapixel Camera

- Auto tilt series imaging

- Tomography reconstruction

- Low-dose technique

- Application areas:

- TEM and Cryo TEM of soft matter samples, Cryo TEM Tomography

Scios 2 HiVac – Focused Ion Beam / Scanning Electron Microscopy

- 30 kV FEG

- Gallium-ion-column

- SE, T1, T2 and DBS Detektors

- C and Platin deposition

- Tomography equipment

- EDAX EDX System

- Mikromanipulator

- PraparationPreparation of TEM Lamella

- Auto slice and view (ASNV)

- Avizo

- Application areas:

- SEM imaging, FIB micro/nanostructuring, EDX analysis (point and map analysis), FIB-SEM Tomography, TEM lamellae preparation

SKYSCAN 1272 – µCT

- X-ray source: 20-100 kV, 10 W, <5 μm spot size @ 4 W

- X-ray detector: 16 Mp, 14-bit cooled CCD fiber-optically coupled to scintillator

- Maximum object size 75 mm in diameter using offset scan (27 mm in fast single scan)

- Detail detectability 0.35 μm (16 Mp) at highest magnification

MultiMode 8 with Nanoscope V – AFM

- Contact and Tapping Modes, phase imaging, Nanoindentation etc.

- Resolution up to 0.1 nm, image range maximum 100 µm, depth maximum 2 µm;

- Main applications: Studies on the crystallization behavior of polymers, polymer blends, block copolymers as well as surfaces of metals, semi-metals, nanocomposites etc.; not only surface but also bulk investigations of the samples by microtomy can be carried out.

Vitrobot Mark IV – Vitrification Robot

- PC-controlled device for vitrification (rapid cooling) of aqueous samples

- Optimized for ethane and/or propane as coolants

- Ultrasonically controlled humidification, optimized for operation at 90% – 100% RH; Peltier controlled heating/cooling; chamber temperature 4 – 60 °C

- Automated lift and transfer of the coolant container

- Cryo grids storage box and holder; semi-automated grid transfer

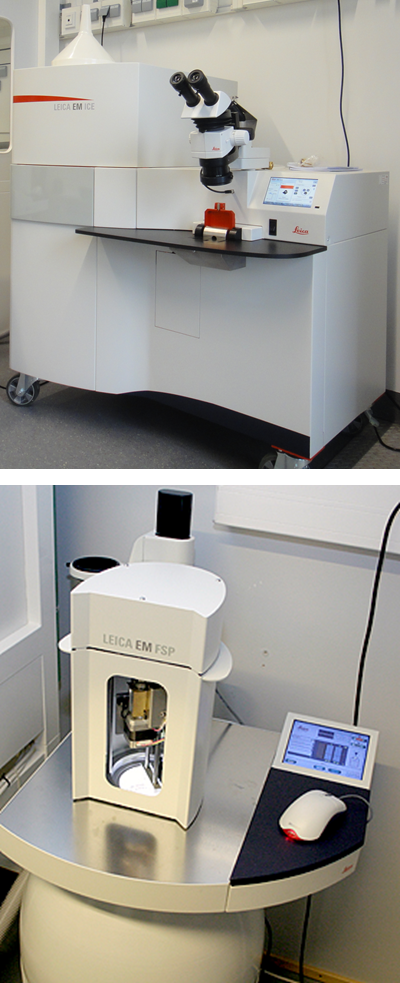

EM ICE with AFS 2 and AF – High Pressure Freezer with Freeze Substitution and Low Temperature Embedding System

- Vitrification of aqueous samples at a pressure of 200 MPa

- Automatic process

- Freeze substitution

- Automatic dosing and embedding

- Light stimulation

Core Facility

Functional Processing

- The Core Facility “Functional Processing” is an asset for the research projects at FIT. It provides technical support for design and manufacturing of multifunctional and intelligent biomimetic polymer multilayer systems. These systems can be applied in biochemical, diagnostic, bioinspired energy harvesting and micro-optical sensor applications.

- The available modules are designed for processing multi-layer systems and allow flexible combinations of the individual process steps. Sample dimensions from a few square centimeters to large-scale roll-to-roll foil formats can be handled.

- The support of the core facility is available to researchers at the University of Freiburg who are working on projects without industrial participation. Equipment fees apply.

- The equipment at the Core Facility is divided into two categories according to operational complexity. For equipment in category 1, evaluated applicants receive training by the Core Facility’s staff, after which they are issued a permit to work on the systems. For category 2, users are not allowed to work alone on the systems; the equipment is operated by the Core Facility’s trained staff.

- If you have any further questions regarding the costs (fee regulation), usage regulations and registration procedure, please contact the management of the Core Facility.

- Scientific Head: Prof. Dr. Claas Müller

- Responsible Manager: Dr. Jing Becker

Category 1: Equipment

Electrophoretic deposition (EPD): Permatecs EPD system and cryomill system

- Pore-free, highly adhesive coatings with functional layers of polymers, ceramics, metals, and combinations thereof.

- Max. voltage: 3000 V, curing temperature: 450°C

Roll-embossing and lamination:

Stork roll laminator HRL 350 Jumbo

- Roll-to-roll nanoimprinting and foil lamination with smooth or structured rolls and adjustable lamination speed.

- Max. temperature: 200°C, max. force: 6 bar

Microscope: Zeiss SteREO Discovery.V12

Category 2: Support by trained stuff of the Core Facility

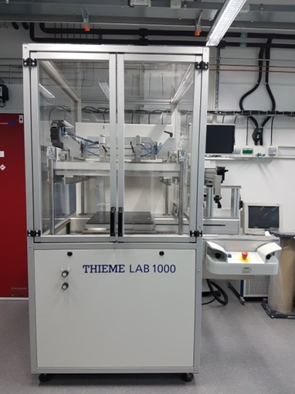

Screen printing: Thieme screen printer LAB 1000

- Screen printing with polymers, metals and ceramics with accurate automatic alignment on pre-structured substrate.

- Alignment accuracy: 5 μm, lateral accuracy: 15 μm

Aerosol jet printing: Neotech AMT AJ 15XA aerosol jet print system

- Mask-less aerosol deposition of functional nanomaterials inks (metals, polymers, ceramics, oxides, biomaterials, …)

- Resolution: 10 μm

Thin film deposition and surface modification: Plasma Electronic Porta 400

- Roll-to-roll film deposition and surface modification, such as hydrophobization or hydrophilization, for large-scale flexible substrates. The manufacturing system combines physical vapor deposition (PVD), chemical vapor deposition (CVD), and plasma-enhanced chemical vapor deposition (PECVD) techniques for deposition of metals, oxides, nitrites and carbides.

- max. foil dimensions: 1000m x 240mm; min. foil thickness: 40 μm

Nano- & micro structure replication: Jenoptik Hex04 embossing machine

- Force- and distance controlled hot-embossing nanoimprint lithography (HE-NIL) of thermoplastic polymers at temperatures up to 450°C, using metal and elastomer stamps.

- max. force: 400 kN, max. roughness: 10 nm

- UV- nanoimprint lithography (UV-NIL) for photoresists and hybrid polymers with hard and soft stamps.

- Alignment accuracy: 2 μm, max. substrate dimensions: 300 mm diameter

Service Group

Modelling and Simulation of Materials Systems

Concept Development, Modeling and Simulation of Interactive Materials Systems

- Multi-scale modeling of molecular systems, complex materials and surfaces

- Ab-initio simulations of catalytic reactions (see figure)Theoretical spectroscopy (UVVis, IR, photoelectron spectroscope, XPS, XAS, Raman)

- Scientific Head: Prof. Dr. Michael Moseler

- Resonsible Manager: PD Dr. Michael Walter