Core Facilities und Service Group

Core Facility

Bildgebung von Materialsystemen

Die 3D‐Visualisierung von komplexen funktionalen und adaptiven (Mikro)Systemen in Natur und Technik gehört zu den zentralen Herausforderungen im Rahmen der Grundlagenforschung an adaptiven und bioinspirierten Technologien sowie der Erforschung von Funktionsprinzipien in biologischen Systemen als Ideengeber für neue technische Entwicklungen.

Durch bereits vorhandene und zusätzlich beschaffte Geräte ist es möglich ein Speziallabor für Mikroskopie und Tomografie von Materialien verbunden mit einem FIT Kompetenznetz 3D-Visualisierung zu etablieren.

Für weitere Fragen zu den anfallenden Kosten (Gebührenordnung), zur Benutzungsordnung und zum Anmeldeverfahren wenden Sie sich bitte an die Leitung der Core Facility.

- Wissenschaftliche Leiterin: Prof. Dr. Anna Fischer

- Verantwortliche Managerin: Dr. Yi Thomann

Geräteübersicht der Core Facility

Talos 200X – HRTEM/HRSTEM

- 200 kV high-brightness X-FEG

- Modes: TEM, STEM, HAAFD, DF, DPC

- SuperX EDX System

- (limited) Cryo TEM, STEM

- TEM Holder: Double Tilt, High Tilt, Cryo

- Piezo-Stage 20 pm

- Low-dose technique

- Ceta 16 Megapixel Digital Camera

- Auto tilt series imaging

- Tomography reconstruction

- Application areas:

- Solid state inorganic and soft matter materials (metals, semiconductors, composites, polymers etc).

- 2D (up to atomic resolution) and 3D imaging.

- 2D EDX analytics (point analysis and mapping).

Talos 120C – TEM

- 120 kV LaB6 gun

- Double Tilt, High Tilt and Cryo Holders

- Ceta 16 Megapixel Camera

- Auto tilt series imaging

- Tomography reconstruction

- Low-dose technique

- Application areas:

- TEM and Cryo TEM of soft matter samples, Cryo TEM Tomography

Scios 2 HiVac – Focused Ion Beam / Scanning Electron Microscopy

- 30 kV FEG

- Gallium-ion-column

- SE, T1, T2 and DBS Detektors

- C and Platin deposition

- Tomography equipment

- EDAX EDX System

- Mikromanipulator

- PraparationPreparation of TEM Lamella

- Auto slice and view (ASNV)

- Avizo

- Application areas:

- SEM imaging, FIB micro/nanostructuring, EDX analysis (point and map analysis), FIB-SEM Tomography, TEM lamellae preparation

SKYSCAN 1272 – µCT

- X-ray source: 20-100 kV, 10 W, <5 μm spot size @ 4 W

- X-ray detector: 16 Mp, 14-bit cooled CCD fiber-optically coupled to scintillator

- Maximum object size 75 mm in diameter using offset scan (27 mm in fast single scan)

- Detail detectability 0.35 μm (16 Mp) at highest magnification

MultiMode 8 with Nanoscope V – AFM

- Contact and Tapping Modes, phase imaging, Nanoindentation etc.

- Resolution up to 0.1 nm, image range maximum 100 µm, depth maximum 2 µm;

- Main applications: Studies on the crystallization behavior of polymers, polymer blends, block copolymers as well as surfaces of metals, semi-metals, nanocomposites etc.; not only surface but also bulk investigations of the samples by microtomy can be carried out.

Vitrobot Mark IV – Vitrification Robot

- PC-controlled device for vitrification (rapid cooling) of aqueous samples

- Optimized for ethane and/or propane as coolants

- Ultrasonically controlled humidification, optimized for operation at 90% – 100% RH; Peltier controlled heating/cooling; chamber temperature 4 – 60 °C

- Automated lift and transfer of the coolant container

- Cryo grids storage box and holder; semi-automated grid transfer

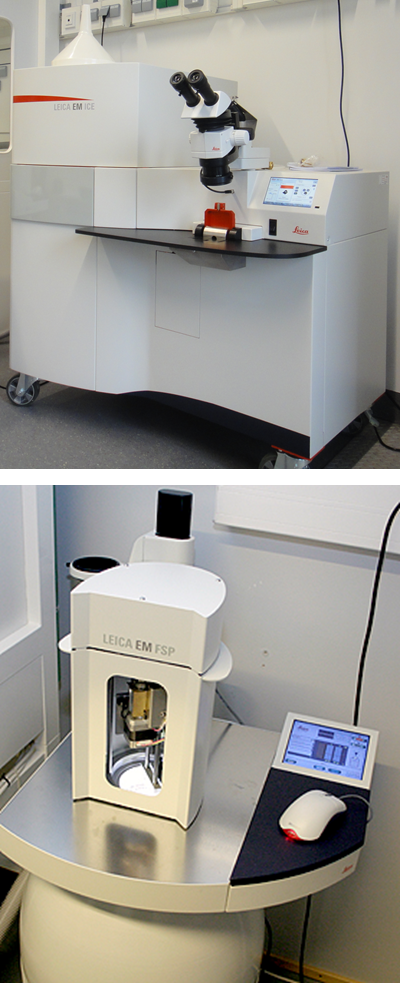

EM ICE with AFS 2 and AF – High Pressure Freezer with Freeze Substitution and Low Temperature Embedding System

- Vitrification of aqueous samples at a pressure of 200 MPa

- Automatic process

- Freeze substitution

- Automatic dosing and embedding

- Light stimulation

Core Facility

Fertigungstechnik

Die Core Facility „Fertigungstechnik“ ist eine wichtige Ergänzung für die Forschungsprojekte am FIT. Die Einrichtung bietet technische Unterstützung bei der Herstellung multifunktionaler und intelligenter biomimetischer Polymer-Mehrschichtsysteme. Diese Systeme können in biochemischen, diagnostischen, bioinspirierten Energy-Harvesting und mikrooptischen Sensoranwendungen eingesetzt werden.

Die verfügbaren Module sind für die Bearbeitung von Mehrschichtsystemen ausgelegt. Die einzelnen Schritte in Herstellungsprozessen können flexibel kombiniert werden. Probengrößen von wenigen Quadratzentimetern bis hin zu großflächigen Rolle-zu-Rolle-Folienformaten sind möglich und können bearbeitet werden.

Der Service der Core Facility steht Wissenschaftler*innen der Universität Freiburg zur Verfügung, die in Projekten ohne Industriebeteiligung forschen. Es fallen Gerätegebühren an.

Die Geräte an der Core Facility sind entsprechend ihrer Komplexität in zwei Kategorien eingeteilt. Für Geräte der Kategorie 1 erhalten Antragsteller eine Schulung durch das Personal der Core Facility, bevor sie die Erlaubnis erhalten, selbst an den Systemen zu arbeiten. Bei Kategorie 2 dürfen die Anwender nicht alleine an den Systemen arbeiten; die Bedienung der Geräte erfolgt durch das geschulte Personal der Core Facility.

Für weitere Informationen zum technischen Support der Core Facility, zu den anfallenden Kosten (Gebührenordnung), zur Benutzungsordnung und zum Anmeldeverfahren wenden Sie sich bitte an die Leitung der Core Facility.

- Wissenschaftlicher Leiter: Prof. Dr. Claas Müller

- Verantwortliche Managerin: Dr. Jing Becker

Kategorie 1: Ausrüstung

Elektrophoretische Deposition (EPD): Permatecs EPD-System und Kryomill-System

- Porenfreie, hochadhäsive Beschichtungen mit Schichten aus Polymeren, Keramiken, Metallen und Kombinationen daraus.

- Max. Spannung: 3000 V, Temp.: 450°C

Rollenprägen und Laminieren: Stork-Rollenlaminator HRL 350 Jumbo

- Rolle-zu-Rolle-Nanoimprinting und Folienlaminierung mit glatten oder strukturierten Rollen und einstellbarer Laminiergeschwindigkeit.

- Max. Temperatur: 200°C, max. Kraft: 6 bar

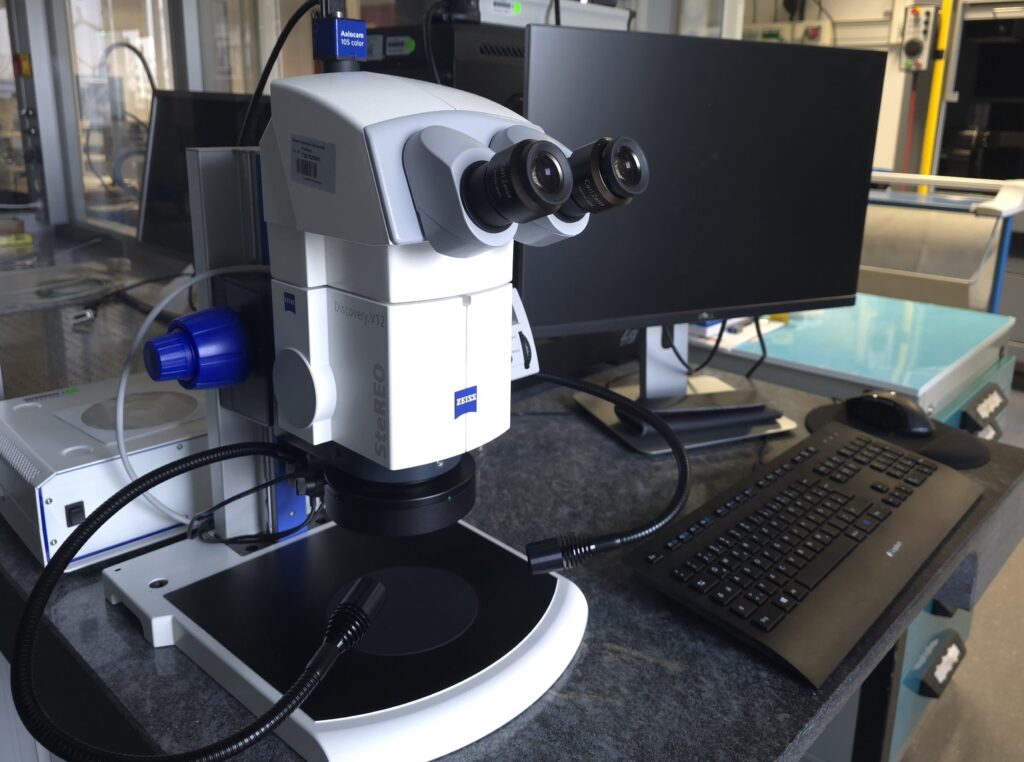

Mikroskop: Zeiss SteREO Discovery.V12

Kategorie 2: Support durch das geschulte Personal der Core Facility

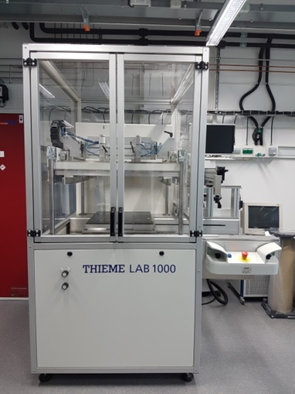

Siebdruck: Thieme Siebdrucker LAB 1000

- Siebdruck mit Polymeren, Metallen und Keramiken mit genauer automatischer Ausrichtung auf vorstrukturiertem Substrat.

- Ausrichtungsgenauigkeit: 5 μm, laterale Genauigkeit: 15 μm

Aerosol-Jet-Druck: Neotech AMT AJ 15XA Aerosol-Jet-Drucksystem

- Maskenloser Aerosoldruck von funktionalen Nanomaterialien (Metalle, Polymere, Keramiken, Oxide, Biomaterialien, …)

- Auflösung: 10 μm

Dünnschichtbeschichtung und Oberflächenmodifikation: Plasma-Elektronik Porta 400

- Maskenloser Aerosoldruck von funktionalen Nanomaterialien (Metalle, Polymere, Keramiken, Oxide, Biomaterialien, …)

- Auflösung: 10 μm

Replikation von Nano- & Mikrostrukturen: Jenoptik Hex04-Prägemaschine

- Kraft- und abstandskontrollierte Heißpräge-Nanoimprint-Lithografie (HE-NIL) von thermoplastischen Polymeren bei Temperaturen bis zu 450°C mit Metall- und Elastomerstempeln.

- max. Kraft: 400 kN, max. Oberflächenrauheit: 10 nm

- UV-Nanoimprint-Lithografie (UV-NIL) für Fotolacke und Hybridpolymere mit harten und weichen Stempeln.

- Ausrichtungsgenauigkeit: 2 μm, maximale Substratabmessungen: 300 mm Durchmesser

Service Group

Modellierung und Simulation von Materialsystemen

Konzeptentwicklung, Modellierung und Simulation interaktiver Materialsysteme

- Skalenübergreifende Modellierung molekularer Systeme, komplexer Materialien und Oberflächen

- Ab-initio Simulationen katalytischer Reaktionen

- Theoretische Spektroskopie (UVVis, IR, Photoelektronspektroskopie, XPS, XAS, Raman)

- Wissenschaftlicher Leiter: Prof. Dr. Michael Moseler

- Verantwortlicher Manager: PD Dr. Michael Walter